SMART iControl

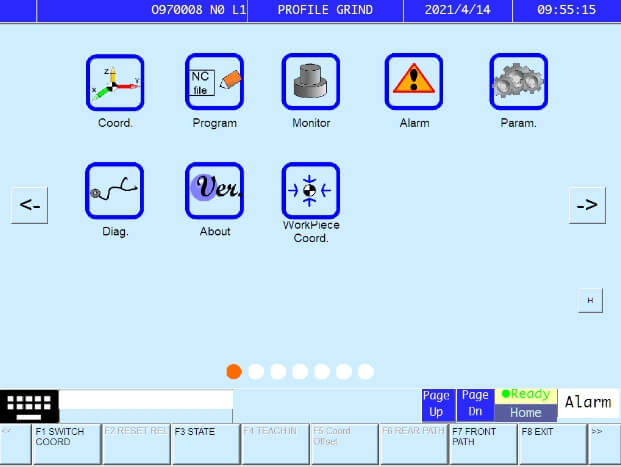

Now, our exclusive next generation SMART iControl delivers a bounty of benefits. Users no longer need to write complicated programs and memorize detailed variables. Instead, they can complete huge, complex processing programs and perform intricate grinding. The powerful computing ability enhances the HMI for better grinding accuracy and with data analysis from network connectivity allows managers to improve the production process and increase output.

Control Features and Benefits

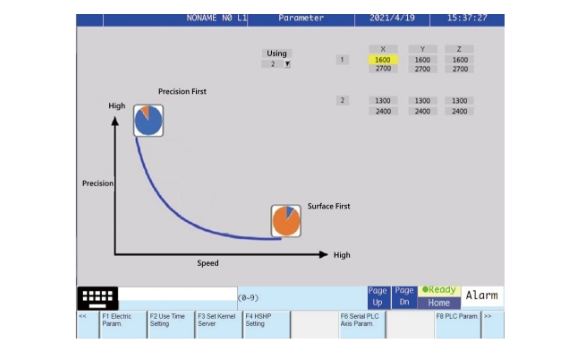

Sets parameters based on prioritizing the machining process for precision or speed in order to improve application efficiency.

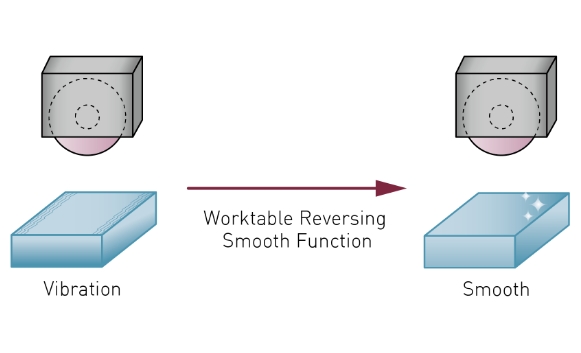

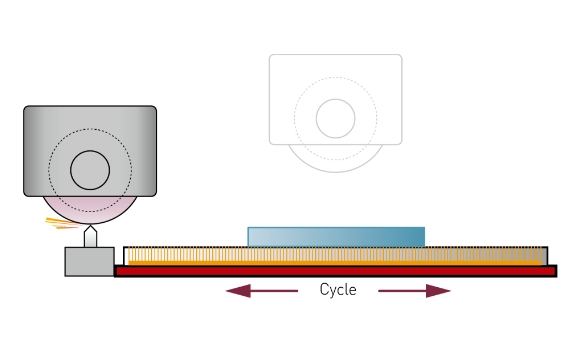

Low-frequency vibration is suppressed during reciprocating motion to enhance the surface finish of the workpiece and improve efficiency.

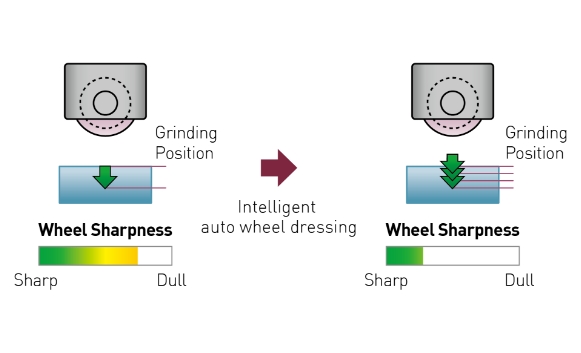

This function detects when the wheel needs to reach optimal cutting efficiency regardless of operator experience to avoid poor grinding quality.

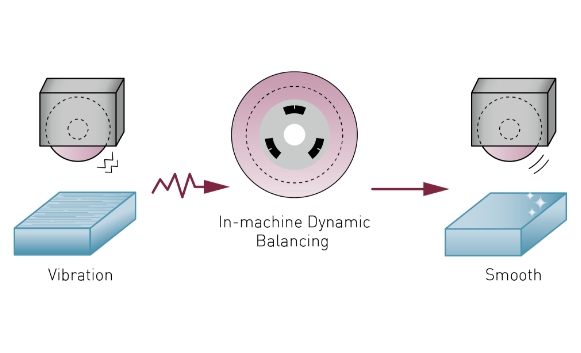

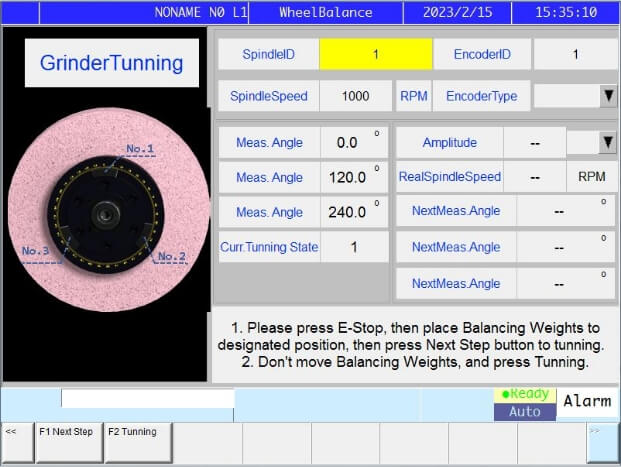

Operator can manually adjust the grinding wheel balance to reduce wheel vibration and eliminate chatter marks to improve grinding quality.

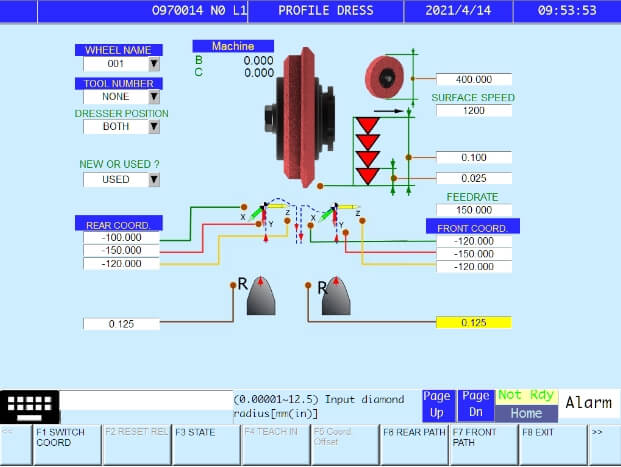

An automatic wheel dressing with compensation feature dresses the wheel automatically during rough and/or fine grinding and again at the end of rough grinding. This enables the machine to run unattended for hours, making it ideal for high-volume production runs, while reducing machining costs and increasing line productivity.

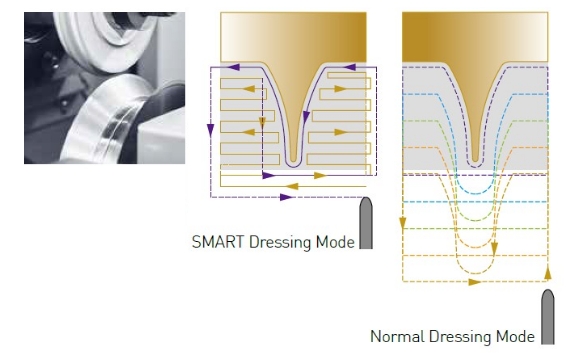

A normal dressing mode wastes time by cutting in air. The SMART iControl dressing mode never cuts air because the diamond is in constant-contact with the wheel to minimizes dress time.

- The SMART iControl supports M3 serial communication servo systems, a communication bandwidth increased to 100Mbps and with support for 24-bit resolution, to improve reading speed and processing smoothness.

- High computing capabilities of 2,000 single blocks per second produce high-precision smoothness, high-precision contour control, machining path smoothing, multi-group working conditions and quick parameter setting to significantly improve the grinding machine’s accuracy and flatness.

- Up to eight CNC axes can be controlled for multifunction machining requirements and 4-axis simultaneous control for complex form grinding.

- The SRI interface communication IO module adds extra IO points (optional) and connects other automation equipment to meet future automation needs.

- The SMART iControl comes standard with a 10.4" LCD high color monitor with HMI.

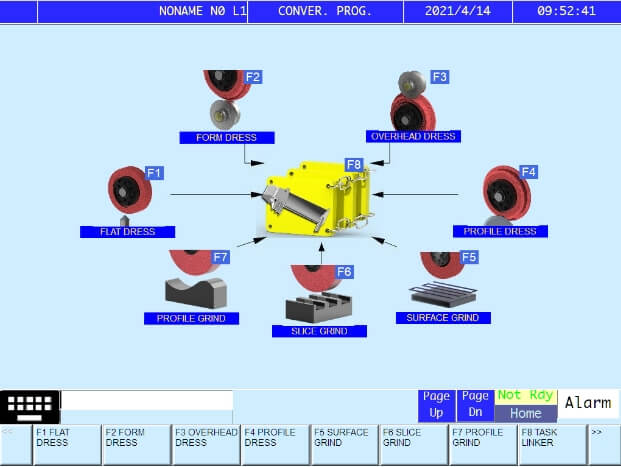

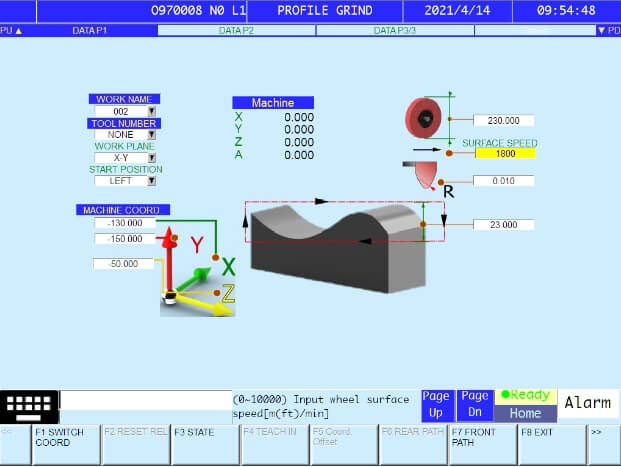

- The three-dimensional graphic image display minimizes text descriptions and looks very similar to the actual workpieces.

Video

【CHEVALIER】SMART iControl 4 Online Product Launch