Vertical Machining Center

A vertical machining center, also known as a VMC machine, is a processing machine with the spindle axis running in the vertical direction. It uses the vertical spindle to accommodate cutting tools such as end mills, drills, and taps. Instructions are programmed through CNC to control tool paths, cutting speeds, feeds, depth of cut, tool changes, and other parameters required to accurately machine the workpiece for precise positioning and cutting in three dimensions.

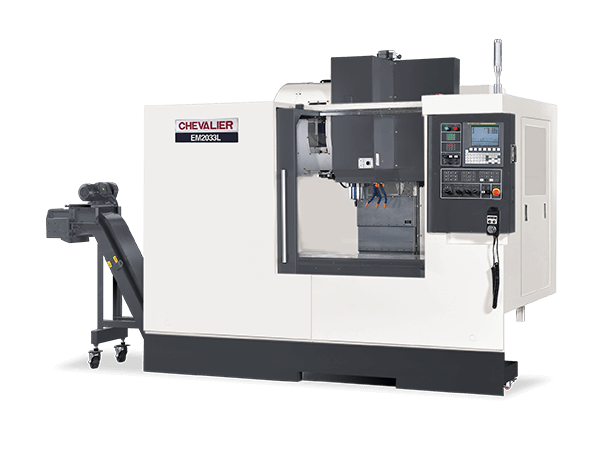

As a famous vertical machining center manufacturer in Taiwan, FALCON provides the QP-L and EM series VMC machines which are efficiently designed with powerful functionality and a reliable vertical machining center that can meet the need for large quantity machining with shorter cycling time.

Advantages of FALCON Vertical Machining Center

- Versatility: Can perform a wide range of machining operations, making them versatile for different industries and applications.

- Precision and Accuracy: Offer high precision and accuracy, crucial for producing complex components with tight tolerances.

- Efficient Chip Evacuation: Come with efficient chip evacuation systems to maintain cleanliness and prevent chip buildup during machining.

- Cost-Effective Production: This can be cost-effective for small to medium batch production, offering competitive machining rates and quick turnaround times.

- 5. Ease of Programming: Our VMC machine often features user-friendly CNC controls and programming software, allowing operators to create and run machining programs with ease.

Vertical Machining Center Applications

- Precision Machining: VMC machines are widely used for precision machining tasks that require tight tolerances and accurate dimensional control such as aerospace, automotive, medical device manufacturing, and electronics for producing intricate components and parts.

- Prototyping and Toolmaking: VMCs are suitable for prototyping new designs and creating molds, dies, and tooling. Their versatility allows engineers and designers to quickly iterate and refine designs before full-scale production.

- Small to Medium Batch Production: The vertical machining centers are efficient for small to medium batch production runs due to their ability to handle various materials, complex geometries, and quick setup times. They are commonly used in job shops and manufacturing facilities for producing custom or specialty parts.

- Milling Operations: VMCs excel in milling operations such as face milling, contouring, pocketing, drilling, and tapping. They can work with a wide range of materials including metals, plastics, and composites.