Renewable Energy Industry

Total

4

-

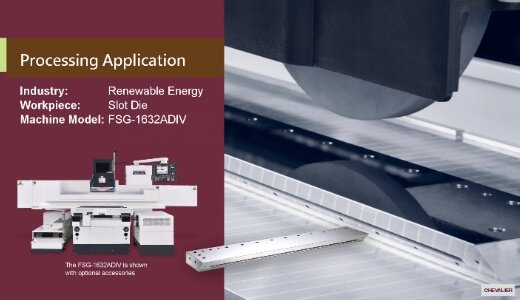

Slot die is the key component of the coating machine in electric vehicle industry. The quality of slot die will directly affect the uniformity of the lithium battery. For the requirements of high precision and surface roughness required in mold industry, Chevalier provide FSG-1632ADIV Fully Automatic Precision Surface Grinder. iSurface control's data sets the in-machine dynamic balancing function to reduce the grinding wheel vibration and eliminating the workpiece surface ripple to improve grinding quality. Surface grinding processing is suitable for various high precision slot dies that require good surface roughness and flatness.

-

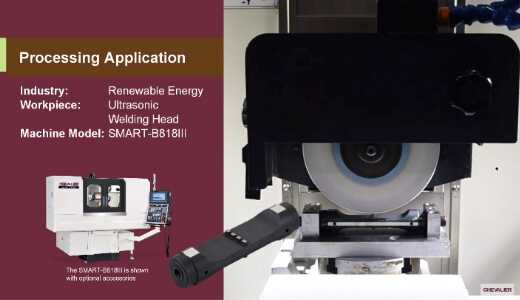

The ultrasonic welding head is an important component of ultrasonic welding machine, which is mainly used to transfer high-frequency vibration to the metal surface through the ultrasonic welding head, so that the two surfaces can rub against each other and fuse together, and is often used to weld two identical or different materials, such as wire harnesses or lithium battery tabs of electric vehicles. Our SMART series with a vertical rotary table and Chevalier's self-developed graphical human-machine interface allow users to easily grind tiny teeth on ultrasonic welding heads. Combined with TaskLink, it allows operators to create their own programs for generating complex grinding tasks in a single cycle—without an engineering degree.

-

In the mold industry, high precision and surface roughness are the main market requirements. Chevalier provides FSG-2048ADIV fully automatic precision surface grinder, which is equipped with a hydrodynamic spindle to effectively reduce vibration, achieve mirror grinding effect and powerful grinding performance, and is equipped with iSurface control, so that the stamping mold can achieve good surface roughness and flatness.

-

FSG-2048ADIV traveling column, 3-axis, fully automatic precision surface grinder improved grinding performance, precision stronger rigidity produces less vibration and smoother movement for years of consistent, reliable operation along with several newly designed features, including: a traveling column structure to further reduce vibration and achieve higher accuracy, a spindle that can withstand heavy load grinding and a double-V guideway for smooth, stable longitudinal movements.