Aerospace Industry

Total

4

-

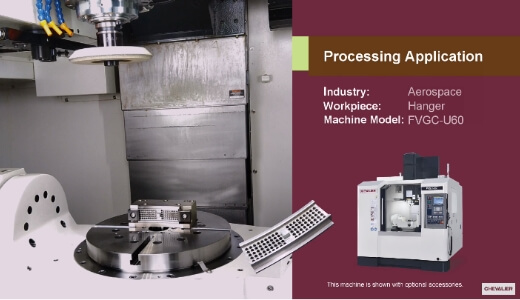

Chevalier designed and implemented an automated production line for grinding hangers for the aerospace industry. Through multi-machine automation integration of complex processes, Chevalier effectively improved process accuracy and save labor costs.

-

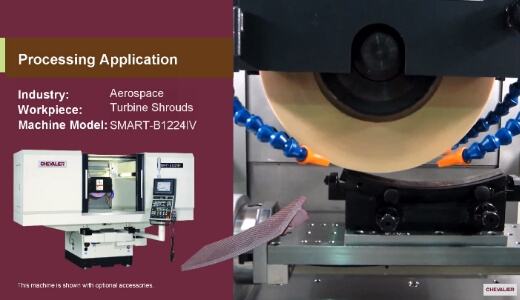

Chevalier's SMART-B1224IV provide a special graphic dialogue for contour grinding and dressing, input relevant dimensions according to the drawings and reduce invalid grinding actions to improve efficiency and be applicable. Available in various Turbine Shrouds specifications.

-

Composite materials are important structural materials for the aerospace industry. In order to understand the characteristics of the material, it needs to be tested on the composite specimen. This workpiece is used in material testing (impact, tensile, shear....) as a specimen to determine the properties of the material. Chevalier's SMART-B1224III can meet the grinding requirements of specimen shaped such as sheet slot cutting, dog-bone profile grinding, V-notch slot grinding, etc.

-

The FVGC series is completely sealed for process filtration. The series is equipped with either a hydrocyclone or centrifugation system, both of which are consumable-free. The environmentally friendly centrifugation system recycles debris from the grinding process, allowing chips, impurities and power to be completely filtered and separated. It also increases the longevity of the cutting fluid and improves workpiece grinding accuracy.