Core Competence

R&D

FALCON Machine Tools Co., Ltd. is a professional manufacturer with expertise in grinders, lathes, and milling machines, and we take pride in our extensive global customer base. Our CHEVALIER brand CNC machines provide intelligent manufacturing solutions to various industries and have always strived to stay at the forefront of technological innovation and green transformation.

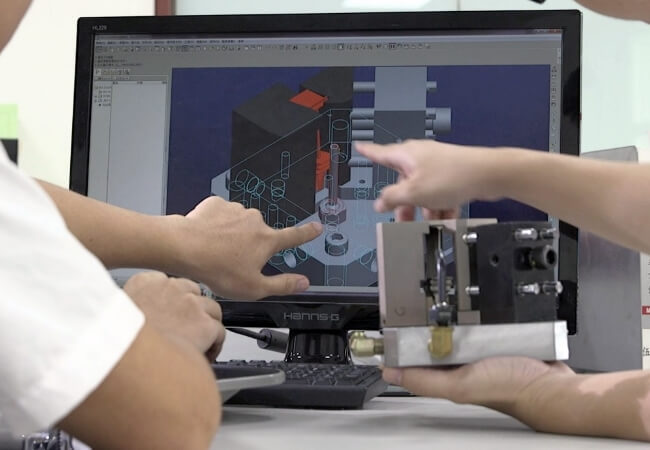

Our R&D team, through continuous collaboration and brainstorming, relentlessly pursues excellence in designing machinery that aligns with ergonomics, user-friendliness, and market trends. Furthermore, we are committed to continuously improving customized products to meet customer demands for automation, the Internet of Things (IoT), and big data analytics.

Our design team proactively gathers information on machine grinding and dressing processes, utilizing in-depth analysis and continuous learning to establish optimal grinding and dressing models. Our latest introduction, the SMART iControl CNC system, offers simplified operation, eliminating the need for complex programming. When combined with TaskLink, it significantly enhances production efficiency.

Additionally, our iMCS (iMachine Communications System) not only collects critical data, parameters, and process information but also efficiently communicates with controllers from different machine brands. This means you can remotely monitor production status anytime, anywhere, achieving the goal of a smart manufacturing facility.

Equipments

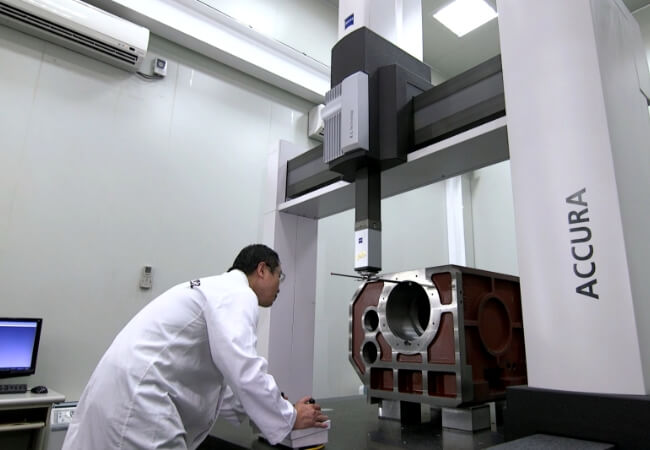

In order to quickly meet our customers' demands for high-precision equipment, CHEVALIER has established an advanced machining department. This decision reflects our commitment to quality and precision in response to our customers' ever-increasing requirements.

We will continue to work tirelessly to ensure that our products excel in high-precision application.

Assembly Line

CHEVALIER builds high-quality machinery based on state-of-the-art CNC manufacturing equipment, combining professional skills with meticulous attention to detail. All precision machining processes are supervised by a rigorously trained and experienced technical team, encompassing all mechanical and electrical assembly operations, including automation control.

We meticulously record all assembly steps and test results to facilitate rapid after service in the future. These records not only provide comprehensive production histories but also document our continuous improvement efforts in production operations.

After assembly, testing and verification are indispensable steps. They ensure the reliability and stability of our production equipment in real-world applications.

The assembly of high-precision equipment is an art, challenging and rewarding. It requires not only technical expertise, but also a relentless commitment to product quality. This is what we dedicate ourselves to in product assembly.

Quality Control & Equipment

We are committed to providing excellent product quality and strictly adhere to the ISO 9001 international standard to ensure customer satisfaction.

Here are some of our key practices for quality assurance:

We possess comprehensive precision measurement equipment to ensure a high level of accuracy and efficiency in the production process. This highly automated measurement equipment helps reduce the risk of human errors while enhancing the consistency of production quality.

We have implemented rigorous quality control procedures, starting from the careful selection and inspection of raw materials, all the way through product manufacturing to final testing. We employ advanced testing and inspection tools to ensure that each product meets the highest quality standards.