Intelligent Manufacturing iMCS

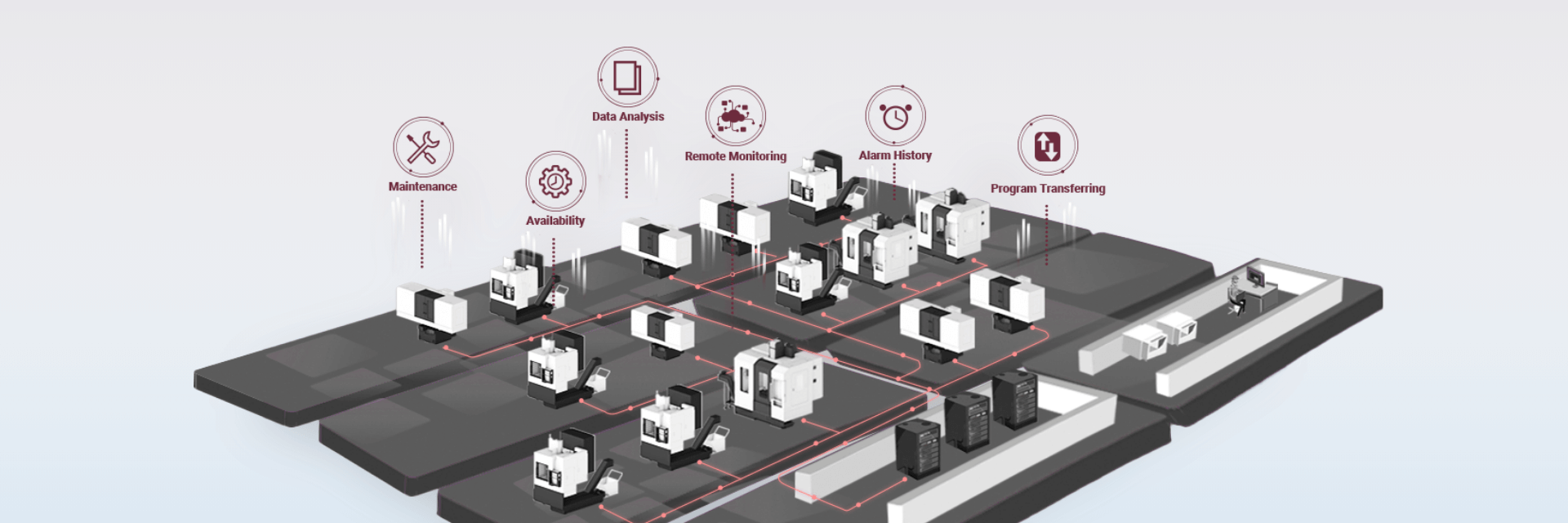

Chevalier's exclusive intelligent Machine Communications System™ (iMCS) is a comprehensive remote monitoring system that connects clients with Chevalier through international communications protocol (MTConnect / OPC UA / umati) to compile performance data, remote machine monitoring, alarm history, maintenance, data analysis and overall equipment effectiveness (OEE).

iMCS software is user friendly, IoT ready and specifically designed for an end-user’s analytic needs. This level of monitoring fosters a greater understanding of production assessment that leads to streamlining and maintaining operations for greater efficiency and productivity.

iMCS Features and Benefits

Monitoring of machine condition and real-time machine data

Statistical analysis of all machine conditions

Tranfer of files seamlessly between CNC controls and management center

Assessment of machine system and components through on-line system diagnostics

Preprogrammed service and maintenance recommendations

Real-time production management with data collection statistics

Concept Map

-

Application platform

This application is for visualizing information, big data analytics and forecasting. Chevalier provides various application platforms for customers according to their needs: CiFactory by Chevalier, StateMonitor by Heidenhain, MT-LINKi by Fanuc, SkyMars by Chevalier and other compatible application platforms.

-

Data collection

To perform data collection and translation of information among these various communication protocols, Chevalier’s iBOX™ integrates with IoT functions to connect machines through these protocols: OPC UA, umati or MTConnect regardless of the control — Chevalier, Fanuc, Siemens, Heidenhain and other various controls.

BIG dataData collection for use by other application systems.

AI- Chevalier's intelligent grinding function provides the best grinding parameters according to the data captured by the machine.

- Our intelligent cutting fuction provides an appropriate temperature compensation mechanism in accordance with the machine’s temperature detector.

-

Device

All Chevalier machines function with iBOX connections. A machine’s sensors send signals regarding temperature or vibration information directly to the iBOX for data collection. After data analysis, the message is transferred back to the machine’s CNC control.

The iBOX has the ability to connect to existing machinery in the factory. The general-purpose communication standards, such as MTConnect, OPC UA and umati protocols, are supported. Chevalier provides an open development environment in which production devices can be connected and converted into production data. A device layer includes machine, sensors, robots and other devices.

| Connections | |

|---|---|

| iBOX | 1~4 |

| 1~7 | |

| 1~10 |

Video

intelligent Machine Communications System (iMCS)