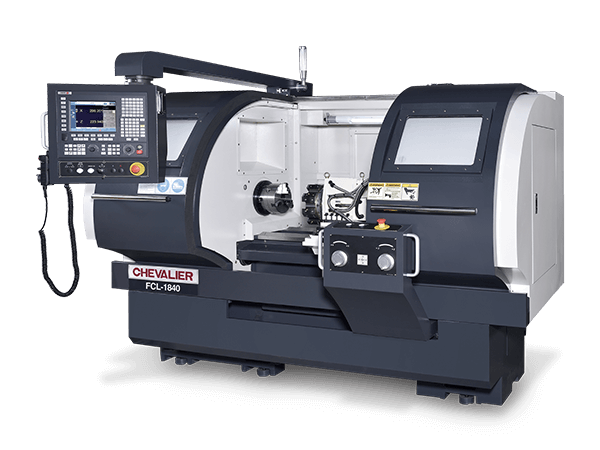

Multifunctional CNC Lathes

Features

Flexible Manual, Teaching and CNC Machining Operations

Chevalier's FCL Series of high-precision, multi-function CNC lathes offer enhanced efficiency by utilizing manual or teach modes or combining them to machine simple and complex parts.

This series is especially suitable for single-part or small-batch production, training CNC lathe operators and long-part turning in the petroleum, shipbuilding and metallurgical equipment industries.

Specifications

| Item | Description | FCL-1840 |

|---|---|---|

| Capacity | Swing over bed | Ø460 mm (18.1") |

| Swing over cross slide | Ø230 mm (9.1") | |

| Max. cutting diameter | Ø460 mm (18.1") | |

| Distance between centers | 1,000 mm (39.4") | |

| Spindle | Spindle speed | 33~3,100 rpm |

| Spindle nose type | D1-6 | |

| Spindle bore | Ø56 mm (2.2") | |

| Taper in spindle | 1/20 | |

| Travel | X-travel | 280 mm (11.0") |

| Z-travel | 900 mm (35.4") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | Ø25 mm / 5 mm (Ø0.98" / 0.19") | |

| Z-axis ball screw dia. | Ø40 mm / 10 mm (Ø1.57" / 0.39") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 25 mm (0.98") | |

| Tailstock | Diameter | Ø75 mm (Ø3.0") |

| Travel | 190 mm (7.5") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 7.5 kW |

| Axis motors (X/Z) | X/Z:1.4 kW | |

| Machine dimensions | Floor space (W x D x H) | 2,840 x 1,905 x 2,235 mm (111.8" x 75.0" x 88.0") |

| Net weight | 2,900 kg (6,380 lbs.) |

| Item | Description | FCL-1860 |

|---|---|---|

| Capacity | Swing over bed | Ø460 mm (18.1") |

| Swing over cross slide | Ø230 mm (9.1") | |

| Max. cutting diameter | Ø460 mm (18.1") | |

| Distance between centers | 1,500 mm (59.1") | |

| Spindle | Spindle speed | 33~3,100 rpm |

| Spindle nose type | D1-6 | |

| Spindle bore | Ø56 mm (2.2") | |

| Taper in spindle | 1/20 | |

| Travel | X-travel | 280 mm (11.0") |

| Z-travel | 1,400 mm (55.1") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | Ø25 mm / 5 mm (Ø0.98" / 0.19") | |

| Z-axis ball screw dia. | Ø40 mm / 10 mm (Ø1.57" / 0.39") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 25 mm (0.98") | |

| Tailstock | Diameter | Ø75 mm (Ø3.0") |

| Travel | 190 mm (7.5") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 7.5 kW |

| Axis motors (X/Z) | X/Z:1.4 kW | |

| Machine dimensions | Floor space (W x D x H) | 3,340 x 1,905 x 2,235 mm (131.5" x 75.0" x 88.0") |

| Net weight | 3,400 kg (7,480 lbs.) |

| Item | Description | FCL-2140 |

|---|---|---|

| Capacity | Swing over bed | Ø540 mm (21.3") |

| Swing over cross slide | Ø310 mm (12.2") | |

| Max. cutting diameter | Ø540 mm (21.3") | |

| Distance between centers | 1,000 mm (39.4") | |

| Spindle | Spindle speed | 27~2,250 rpm (D1-8), optional 80~1,500 rpm |

| Spindle nose type | D1-8, optional A2-11 | |

| Spindle bore | Ø85 mm (D1-8), optional Ø105 mm (A2-11) (Ø3.3" (D1-8), optional Ø4.1" (A2-11)) |

|

| Taper in spindle | 1/20 | |

| Travel | X-travel | 280 mm |

| Z-travel | 850 mm (33.5") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | Ø25 mm / 5 mm (Ø0.98" / 0.19") | |

| Z-axis ball screw dia. | Ø40 mm / 10 mm (Ø1.57" / 0.39") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 25 mm (0.98") | |

| Tailstock | Diameter | Ø75 mm (Ø3.0") |

| Travel | 190 mm (7.5") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 15.5 kW |

| Axis motors (X/Z) | X/Z:1.4 kW | |

| Machine dimensions | Floor space (W x D x H) | 2,840 x 1,905 x 2,235 mm (111.8" x 75.0" x 88.0") |

| Net weight | 2,900 kg (6,380 lbs.) |

| Item | Description | FCL-2160 |

|---|---|---|

| Capacity | Swing over bed | Ø540 mm (21.3") |

| Swing over cross slide | Ø310 mm (12.2") | |

| Max. cutting diameter | Ø540 mm (21.3") | |

| Distance between centers | 1,500 mm (59.1") | |

| Spindle | Spindle speed | 27~2,250 rpm (D1-8), optional 80~1,500 rpm |

| Spindle nose type | D1-8, optional A2-11 | |

| Spindle bore | Ø85 mm (D1-8), optional Ø105 mm (A2-11) (Ø3.3" (D1-8), optional Ø4.1" (A2-11)) |

|

| Taper in spindle | 1/20 | |

| Travel | X-travel | 280 mm |

| Z-travel | 1,350 mm (53.1") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | Ø25 mm / 5 mm (Ø0.98" / 0.19") | |

| Z-axis ball screw dia. | Ø40 mm / 10 mm (Ø1.57" / 0.39") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 25 mm (0.98") | |

| Tailstock | Diameter | Ø75 mm (Ø3.0") |

| Travel | 190 mm (7.5") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 15.5 kW |

| Axis motors (X/Z) | X/Z:1.4 kW | |

| Machine dimensions | Floor space (W x D x H) | 3,340 x 1,905 x 2,235 mm (131.5" x 75.0" x 88.0") |

| Net weight | 3,400 kg (7,480 lbs.) |

| Item | Description | FCL-2180 |

|---|---|---|

| Capacity | Swing over bed | Ø540 mm (21.3") |

| Swing over cross slide | Ø310 mm (12.2") | |

| Max. cutting diameter | Ø540 mm (21.3") | |

| Distance between centers | 2,000 mm (78.7") | |

| Spindle | Spindle speed | 27~2,250 rpm (D1-8), optional 80~1,500 rpm |

| Spindle nose type | D1-8, optional A2-11 | |

| Spindle bore | Ø85 mm (D1-8), optional Ø105 mm (A2-11) (Ø3.3" (D1-8), optional Ø4.1" (A2-11)) |

|

| Taper in spindle | 1/20 | |

| Travel | X-travel | 280 mm |

| Z-travel | 1,850 mm (72.8") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | Ø25 mm / 5 mm (Ø0.98" / 0.19") | |

| Z-axis ball screw dia. | Ø40 mm / 10 mm (Ø1.57" / 0.39") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 25 mm (0.98") | |

| Tailstock | Diameter | Ø75 mm (Ø3.0") |

| Travel | 190 mm (7.5") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 15.5 kW |

| Axis motors (X/Z) | X/Z:1.4 kW | |

| Machine dimensions | Floor space (W x D x H) | 3,840 x 1,905 x 2,235 mm (151.2" x 75.0" x 88.0") |

| Net weight | 4,200 kg (9,240 lbs.) |

| Item | Description | FCL-2540 |

|---|---|---|

| Capacity | Swing over bed | Ø630 mm (24.8") |

| Swing over cross slide | Ø400 mm (15.7") | |

| Max. cutting diameter | Ø630 mm (24.8") | |

| Distance between centers | 1,000 mm (39.4") | |

| Spindle | Spindle speed | 37~2,250 rpm (D1-8), optional 80~1,500 rpm/10~800 rpm (A2-11) |

| Spindle nose type | D1-8, optionla A2-11 | |

| Spindle bore | Ø85 mm (D1-8), optional Ø105 mm (A2-11) (Ø3.3" (D1-8), optional Ø4.1" (A2-11)) |

|

| Taper in spindle | 1/16, optional 1/20 | |

| Travel | X-travel | 280 mm |

| Z-travel | 850 mm (33.5") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | Ø25 mm / 5 mm (Ø0.98" / 0.19") | |

| Z-axis ball screw dia. | Ø40 mm / 10 mm (Ø1.57" / 0.39") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 25 mm (0.98") | |

| Tailstock | Diameter | Ø75 mm (Ø3.0") |

| Travel | 190 mm (7.5") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 15.5 kW |

| Axis motors (X/Z) | X/Z:1.4 kW | |

| Machine dimensions | Floor space (W x D x H) | 2,840 x 1,905 x 2,235 mm (111.8" x 75.0" x 88.0") |

| Net weight | 3,350 kg (7,370 lbs.) |

| Item | Description | FCL-2560 |

|---|---|---|

| Capacity | Swing over bed | Ø630 mm (24.8") |

| Swing over cross slide | Ø400 mm (15.7") | |

| Max. cutting diameter | Ø630 mm (24.8") | |

| Distance between centers | 1,500 mm (59.1") | |

| Spindle | Spindle speed | 37~2,250 rpm (D1-8), optional 80~1,500 rpm/10~800 rpm (A2-11) |

| Spindle nose type | D1-8, optionla A2-11 | |

| Spindle bore | Ø85 mm (D1-8), optional Ø105 mm (A2-11) (Ø3.3" (D1-8), optional Ø4.1" (A2-11)) |

|

| Taper in spindle | 1/16, optional 1/20 | |

| Travel | X-travel | 280 mm |

| Z-travel | 1,350 mm (53.1") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | Ø25 mm / 5 mm (Ø0.98" / 0.19") | |

| Z-axis ball screw dia. | Ø40 mm / 10 mm (Ø1.57" / 0.39") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 25 mm (0.98") | |

| Tailstock | Diameter | Ø75 mm (Ø3.0") |

| Travel | 190 mm (7.5") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 15.5 kW |

| Axis motors (X/Z) | X/Z:1.4 kW | |

| Machine dimensions | Floor space (W x D x H) | 3,340 x 1,905 x 2,235 mm (131.5" x 75.0" x 88.0") |

| Net weight | 3,850 kg (8,470 lbs.) |

| Item | Description | FCL-2580 |

|---|---|---|

| Capacity | Swing over bed | Ø630 mm (24.8") |

| Swing over cross slide | Ø400 mm (15.7") | |

| Max. cutting diameter | Ø630 mm (24.8") | |

| Distance between centers | 2,000 mm (78.7") | |

| Spindle | Spindle speed | 37~2,250 rpm (D1-8), optional 80~1,500 rpm/10~800 rpm (A2-11) |

| Spindle nose type | D1-8, optionla A2-11 | |

| Spindle bore | Ø85 mm (D1-8), optional Ø105 mm (A2-11) (Ø3.3" (D1-8), optional Ø4.1" (A2-11)) |

|

| Taper in spindle | 1/16, optional 1/20 | |

| Travel | X-travel | 280 mm |

| Z-travel | 1,850 mm (72.8") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | Ø25 mm / 5 mm (Ø0.98" / 0.19") | |

| Z-axis ball screw dia. | Ø40 mm / 10 mm (Ø1.57" / 0.39") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 25 mm (0.98") | |

| Tailstock | Diameter | Ø75 mm (Ø3.0") |

| Travel | 190 mm (7.5") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 15.5 kW |

| Axis motors (X/Z) | X/Z:1.4 kW | |

| Machine dimensions | Floor space (W x D x H) | 3,840 x 1,905 x 2,235 mm (151.2" x 75.0" x 88.0") |

| Net weight | 4,200 kg (9,240 lbs.) |

| Item | Description | FCL-3060 |

|---|---|---|

| Capacity | Swing over bed | Ø760 mm (29.9") |

| Swing over cross slide | Ø500 mm (19.7") | |

| Max. cutting diameter | Ø760 mm (29.9") | |

| Distance between centers | 1,500 mm (59.1") | |

| Spindle | Spindle speed | 80~1,500 rpm |

| Spindle nose type | A2-11 | |

| Spindle bore | Ø105 mm (Ø4.1") A2-11 | |

| Taper in spindle | 1/20 | |

| Travel | X-travel | 450 mm (17.7") |

| Z-travel | 1,480 mm (58.3") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | X: Ø25 / 5 mm (Ø0.98" / 0.19") | |

| Z-axis ball screw dia. | Z: Ø40 / 10 mm (Ø1.57" / 0.39") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 25 mm (0.98") | |

| Tailstock | Diameter | Ø80 mm, optional Ø105 mm (Ø3.1", optional Ø4.1") |

| Travel | 220 mm ( 8.7") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 15.5 kW |

| Axis motors (X/Z) | X/Z:1.4 kW | |

| Machine dimensions | Floor space (W x D x H) | 3,815 x 2,134 x 2,275 mm (150.2" x 84.0" x 89.5") |

| Net weight | 4,400 kg (9,680 lbs.) |

| Item | Description | FCL-3080 |

|---|---|---|

| Capacity | Swing over bed | Ø760 mm (29.9") |

| Swing over cross slide | Ø500 mm (19.7") | |

| Max. cutting diameter | Ø760 mm (29.9") | |

| Distance between centers | 2,000 mm (78.7") | |

| Spindle | Spindle speed | 80~1,500 rpm |

| Spindle nose type | A2-11 | |

| Spindle bore | Ø105 mm (Ø4.1") A2-11 | |

| Taper in spindle | 1/20 | |

| Travel | X-travel | 450 mm (17.7") |

| Z-travel | 1,980 mm (78.0") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | X: Ø25 / 5 mm (Ø0.98" / 0.19") | |

| Z-axis ball screw dia. | Z: Ø40 / 10 mm (Ø1.57" / 0.39") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 25 mm (0.98") | |

| Tailstock | Diameter | Ø80 mm, optional Ø105 mm (Ø3.1", optional Ø4.1") |

| Travel | 220 mm ( 8.7") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 15.5 kW |

| Axis motors (X/Z) | X/Z:1.4 kW | |

| Machine dimensions | Floor space (W x D x H) | 4,300 x 2,134 x 2,275 mm (169.3" x 84.0" x 89.5") |

| Net weight | 5,100 kg (11,200 lbs.) |

| Item | Description | FCL-30120 |

|---|---|---|

| Capacity | Swing over bed | Ø760 mm (29.9") |

| Swing over cross slide | Ø500 mm (19.7") | |

| Max. cutting diameter | Ø760 mm (29.9") | |

| Distance between centers | 3,000 mm (118.1") | |

| Spindle | Spindle speed | 80~1,500 rpm |

| Spindle nose type | A2-11 | |

| Spindle bore | Ø105 mm (Ø4.1") A2-11 | |

| Taper in spindle | 1/20 | |

| Travel | X-travel | 450 mm (17.7") |

| Z-travel | 2,980 mm (117.3") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | X: Ø25 / 5 mm (Ø0.98" / 0.19") | |

| Z-axis ball screw dia. | Z: Ø40 / 10 mm (Ø1.57" / 0.39") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 25 mm (0.98") | |

| Tailstock | Diameter | Ø80 mm, optional Ø105 mm (Ø3.1", optional Ø4.1") |

| Travel | 220 mm ( 8.7") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 15.5 kW |

| Axis motors (X/Z) | X/Z:1.4 kW | |

| Machine dimensions | Floor space (W x D x H) | 5,300 x 2,134 x 2,275 mm (208.7"x 84.0" x 89.5") |

| Net weight | 5,600 kg (12,300 lbs.) |

| Item | Description | FCL-3280 |

|---|---|---|

| Capacity | Swing over bed | Ø815 mm (32.1") |

| Swing over cross slide | Ø470 mm (18.5") | |

| Max. cutting diameter | Ø815 mm (32.1") | |

| Distance between centers | 2,000 mm (78.7") | |

| Spindle | Spindle speed | 0~1,200 rpm (D1-11) Ø134 mm (5.2"), optional 0~1,000 rpm Ø160 mm (6.2") |

| Spindle nose type | D1-11,optional A2-11 | |

| Spindle bore | Ø134 mm (5.2") (A2-11, D1-11), optioal Ø160 mm (6.2") (A2-11) | |

| Taper in spindle | 1/20 | |

| Travel | X-travel | 470 mm (18.5") |

| Z-travel | 1,904 mm (75.0") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | X: Ø32 / 10 mm (Ø1.25" / 0.39") | |

| Z-axis ball screw dia. | Z:Ø50 / 10 mm (Ø1.9" / 0.39") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 32 mm (1.26") | |

| Tailstock | Diameter | Ø150 mm (5.9") |

| Travel | Ø250 mm (9.8") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 22 kW 22 kW |

| Axis motors (X/Z) | X/Z:3.6 kW | |

| Machine dimensions | Floor space (W x D x H) | 5,050 x 2,450 x 2,300 mm (198.8" x 96.5" x 90.6") |

| Net weight | 9,600 kg (21,120 lbs.) |

| Item | Description | FCL-32120 |

|---|---|---|

| Capacity | Swing over bed | Ø815 mm (32.1") |

| Swing over cross slide | Ø470 mm (18.5") | |

| Max. cutting diameter | Ø815 mm (32.1") | |

| Distance between centers | 3,000 mm (118.1") | |

| Spindle | Spindle speed | 0~1,200 rpm (D1-11) Ø134 mm (5.2"), optional 0~1,000 rpm Ø160 mm (6.2") |

| Spindle nose type | D1-11,optional A2-11 | |

| Spindle bore | Ø134 mm (5.2") (A2-11, D1-11), optioal Ø160 mm (6.2") (A2-11) | |

| Taper in spindle | 1/20 | |

| Travel | X-travel | 470 mm (18.5") |

| Z-travel | 2,920 mm (115.0") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | X: Ø32 / 10 mm (Ø1.25" / 0.39") | |

| Z-axis ball screw dia. | Z:Ø50 / 10 mm (Ø1.9" / 0.39") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 32 mm (1.26") | |

| Tailstock | Diameter | Ø150 mm (5.9") |

| Travel | Ø250 mm (9.8") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 22 kW 22 kW |

| Axis motors (X/Z) | X/Z:3.6 kW | |

| Machine dimensions | Floor space (W x D x H) | 6,500 x 2,450 x 2,300 mm (255.9" x 96.5" x 90.6") |

| Net weight | 10,500 kg (23,100 lbs.) |

| Item | Description | FCL-32160 |

|---|---|---|

| Capacity | Swing over bed | Ø815 mm (32.1") |

| Swing over cross slide | Ø470 mm (18.5") | |

| Max. cutting diameter | Ø815 mm (32.1") | |

| Distance between centers | 4,000 mm (157.5") | |

| Spindle | Spindle speed | 0~1,200 rpm (D1-11) Ø134 mm (5.2"), optional 0~1,000 rpm Ø160 mm (6.2") |

| Spindle nose type | D1-11,optional A2-11 | |

| Spindle bore | Ø134 mm (5.2") (A2-11, D1-11), optioal Ø160 mm (6.2") (A2-11) | |

| Taper in spindle | 1/20 | |

| Travel | X-travel | 470 mm (18.5") |

| Z-travel | 3,936 mm (155.0") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | X: Ø32 / 10 mm (Ø1.25" / 0.39") | |

| Z-axis ball screw dia. | Z:Ø63 / 12 mm (2.4" / 0.47") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 32 mm (1.26") | |

| Tailstock | Diameter | Ø150 mm (5.9") |

| Travel | Ø250 mm (9.8") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 22 kW 22 kW |

| Axis motors (X/Z) | X/Z:3.6 kW | |

| Machine dimensions | Floor space (W x D x H) | 7,050 x 2,450 x 2,300 mm (277.6" x 96.5" x 90.6") |

| Net weight | 11,500 kg (25,300 lbs.) |

| Item | Description | FCL-4080 |

|---|---|---|

| Capacity | Swing over bed | Ø1,015 mm (40.0") |

| Swing over cross slide | Ø690 mm (27.2") | |

| Max. cutting diameter | Ø1,015 mm (40.0") | |

| Distance between centers | 2,000 mm (78.7") | |

| Spindle | Spindle speed | 0~1,200 rpm (D1-11) Ø134 mm (5.2"), optional 0~1,000 rpm Ø160 mm (6.2") |

| Spindle nose type | D1-11, optional A2-11 | |

| Spindle bore | Ø134 mm (5.2") (A2-11,D1-11), optional Ø160 mm (6.2") (A2-11) | |

| Taper in spindle | 1/20 | |

| Travel | X-travel | 470 mm (18.5") |

| Z-travel | 1,904 mm (75.0") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | X: Ø32 / 10 mm (Ø1.25" / 0.39") | |

| Z-axis ball screw dia. | Z: Ø50 / 10 mm (Ø1.9" / 0.39") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 32 mm (1.26") | |

| Tailstock | Diameter | Ø150 mm (5.9") |

| Travel | Ø250 mm (9.8") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 22 kW |

| Axis motors (X/Z) | X/Z: 3.6 kW | |

| Machine dimensions | Floor space (W x D x H) | 5,050 x 2,450 x 2,300 mm (198.8" x 96.5" x 90.6") |

| Net weight | 9,600 kg (21,120 lbs.) |

| Item | Description | FCL-40120 |

|---|---|---|

| Capacity | Swing over bed | Ø1,015 mm (40.0") |

| Swing over cross slide | Ø690 mm (27.2") | |

| Max. cutting diameter | Ø1,015 mm (40.0") | |

| Distance between centers | 3,000 mm (118.1") | |

| Spindle | Spindle speed | 0~1,200 rpm (D1-11) Ø134 mm (5.2"), optional 0~1,000 rpm Ø160 mm (6.2") |

| Spindle nose type | D1-11, optional A2-11 | |

| Spindle bore | Ø134 mm (5.2") (A2-11,D1-11), optional Ø160 mm (6.2") (A2-11) | |

| Taper in spindle | 1/20 | |

| Travel | X-travel | 470 mm (18.5") |

| Z-travel | 2,920 mm (115.0") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | X: Ø32 / 10 mm (Ø1.25" / 0.39") | |

| Z-axis ball screw dia. | Z: Ø50 / 10 mm (Ø1.9" / 0.39") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 32 mm (1.26") | |

| Tailstock | Diameter | Ø150 mm (5.9") |

| Travel | Ø250 mm (9.8") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 22 kW |

| Axis motors (X/Z) | X/Z: 3.6 kW | |

| Machine dimensions | Floor space (W x D x H) | 6,500 x 2,450 x 2,300 mm (255.9" x 96.5" x 90.6") |

| Net weight | 10,500 kg (23,100 lbs.) |

| Item | Description | FCL-40160 |

|---|---|---|

| Capacity | Swing over bed | Ø1,015 mm (40.0") |

| Swing over cross slide | Ø690 mm (27.2") | |

| Max. cutting diameter | Ø1,015 mm (40.0") | |

| Distance between centers | 4,000 mm (157.5") | |

| Spindle | Spindle speed | 0~1,200 rpm (D1-11) Ø134 mm (5.2"), optional 0~1,000 rpm Ø160 mm (6.2") |

| Spindle nose type | D1-11, optional A2-11 | |

| Spindle bore | Ø134 mm (5.2") (A2-11,D1-11), optional Ø160 mm (6.2") (A2-11) | |

| Taper in spindle | 1/20 | |

| Travel | X-travel | 470 mm (18.5") |

| Z-travel | 3,936 mm (155.0") | |

| Feed rates | Feed rates | 5,000 mm/min (196 ipm) |

| X-axis rapid traverse | 5,000 mm/min (196 ipm) | |

| Z-axis rapid traverse | 8,000 mm/min (314 ipm) | |

| X-axis ball screw dia. | X: Ø32 / 10 mm (Ø1.25" / 0.39") | |

| Z-axis ball screw dia. | Z: Ø63 / 12 mm (Ø2.4" / 0.47") | |

| Turret | Turret type | Manual 4-station tool post |

| O.D. tool shank size | 32 mm (1.26") | |

| Tailstock | Diameter | Ø150 mm (5.9") |

| Travel | Ø250 mm (9.8") | |

| Taper | MT#5 | |

| Motors | Spindle motor | 22 kW |

| Axis motors (X/Z) | X/Z: 3.6 kW | |

| Machine dimensions | Floor space (W x D x H) | 7,050 x 2,450 x 2,300 mm (277.6" x 96.5" x 90.6") |

| Net weight | 11,500 kg (25,300 lbs.) |

All content is for reference only and may be subject to change without prior notice or obligation.