Grinding Machine

Total

9

-

This series CNC grinding machine is designed specifically for the grinding of complex workpieces. By selecting corresponding accessories, fixtures and customized configurations for automation, it can enhance performance, precision, and stability to meet the demand of stringent quality requirements.

-

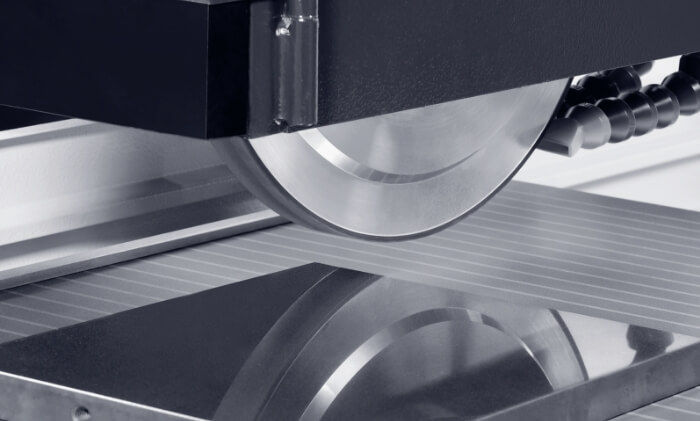

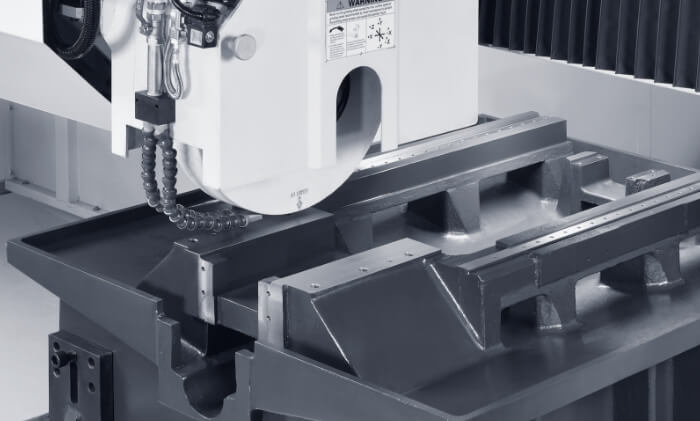

Chevalier's FSG-ADIV Series of surface grinders have several design features to shorten your processing and non-processing preparation while delivering high-precision workpieces year after year.

-

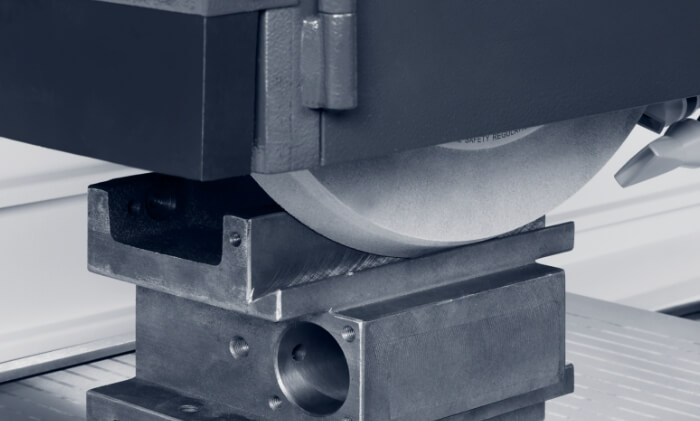

The FVGC Series, which offers a sealed interior and an automatic filtration system, meets the needs of the semiconductor, punch and aerospace industries.

-

The design of our new traveling column high-efficiency profile grinding machine is the standard required by the medical, automotive, mining, semiconductor, aerospace and job shop industries to meet current grinding demands and pave the way to smart manufacturing.

-

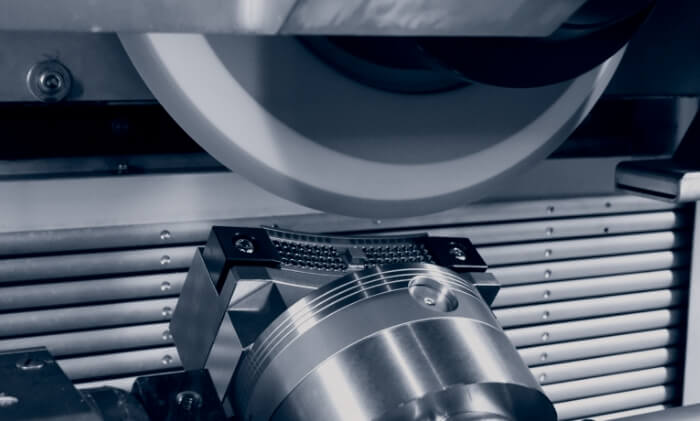

This series of CNC grinding machines is designed to meet current and future intricate profiles, and mold components grinding requirements due to their advanced software, multi-axis control, automation capabilities, precision, and customization options.

-

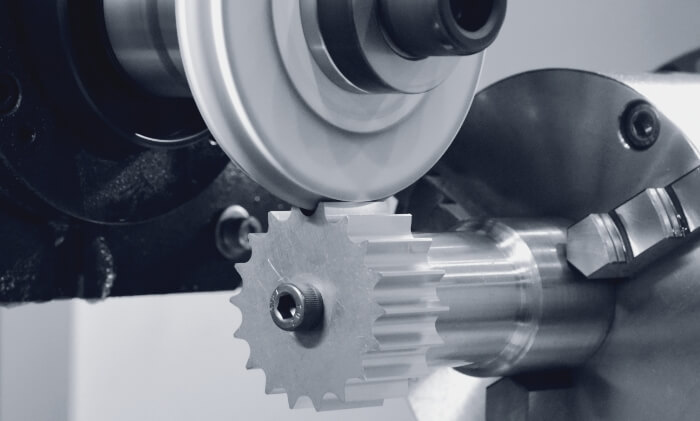

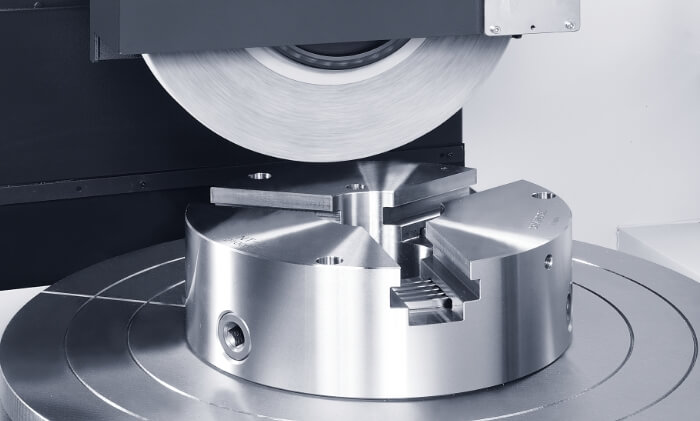

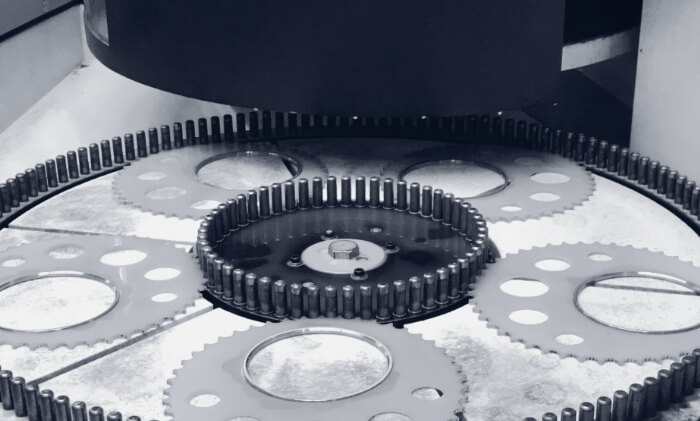

This series features several excellent designs, ensuring a smooth and stable ribbed high-rigidity column structure, capable of handling heavy-load grinding with a fully enclosed hydrostatic rotary table. Easily adapts to future needs for semiconductor, precision chuck, saw blade and spindle transmission components.

-

Equipped with the latest technology, Chevalier's FDG-700 is loaded with features that make the innovative double-sided grinder the ideal machine for a variety of flat, hard and brittle materials.

-

Chevalier's FSG-DC Series stands out as the number one choice for fixed-beam, double column grinders for a variety of important reasons, including: an easy-to-use interface, full CNC user-friendly control system, full workpiece capacity, rigidity and accuracy of the dual column design—all features that offer impressive performance.

-

These words describe the core benefits behind the design of our FSG Series of manual surface and form grinding machines. They set the standards required by the automotive, mining, aerospace and job shop industries in order to meet current and future market needs.