|

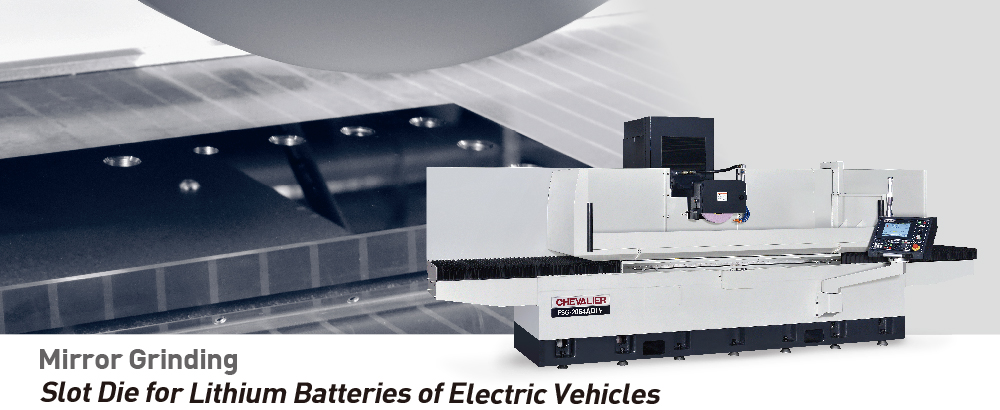

Chevalier’s intelligent CNC grinder is the perfect match for the electric vehicle industry

|

|

This distributor e-newsletter features Falcon Group’s latest developments in electric vehicle lithium batteries; hard and brittle semiconductor materials; and multi-functional equipment.

The two major domestic machine tool shows, Taipei International Machine Tool Show (TIMTOS) and Taiwan International Machine Tool Show Exhibition (TMTS), will be a joint exhibition in 2022, where we will showcase slot-die grinding of lithium batteries’ key components for electric vehicles.

The latest FSG-2064ADIV surface grinder can be equipped with a hydrodynamic spindle, which provides reliable and stable grinding performance and easily achieves a

mirror-finish effect.

The core of our intelligent grinders is our innovative iSurface control, which features in-machine manual dynamic balancing; variable speed spindle; constant surface speed; automatic dressing and compensation; and smart grinding path functions.

We have developed the designs, technologies and solutions to meet the processing needs and solutions of our industrial customers. For the hard and brittle materials of the semiconductor industry, Falcon Group’s machines meet the requirements for filtration, protection, composite high-speed processing, structural rigidity and automation.

|

|

|

Show machine highlights

|

|

|

FSG-2064ADIV Traveling Column, 3-axis, Fully Automatic Precision Surface Grinder

Chevalier’s newly designed FSG-2048ADIV and 2064ADIV join our ADIV CNC surface grinder series. They have multiple design enhancements, including a new double-layer column structure with a heavy-load grinding and double "V" guideway to ensure a smooth, stable grinding operation. This series features a double-V guideway design laminated with Turcite-B anti-friction material for smooth and stable longitudinal movement. Equipped with a new oil-film guideway lubrication system for low-wear, the series easily and effectively achieves mirror grinding while improving grinding accuracy.

|

|

FVGC-50 Vertical Grinding Center

The FVGC Series is completely sealed for process filtration. The series is equipped with either a hydrocyclone or centrifugation system, both of which are consumable-free. The environmentally friendly centrifugation system recycles debris from the grinding process, allowing chips, impurities and powder to be completely filtered and separated. It also increases the longevity of the cutting fluid and improves workpiece grinding accuracy.

The axial protection design creates a completely sealed machine during the grinding operation. It includes a double-layer device that uses a telescopic cover and roller shutter mechanism for waterproofing and anti-chip protection. The metal shavings or hardened powder is removed with a protective scraper attached to the telescopic cover.

|

|

FNL-220LSY Multi-axis, Multi-functional, Multi-operational

The FNL-220LSY is designed with a 30-degree, true slant-bed, linear-roller guideway structure and a 60-degree, compound Y-axis, all which ensure the highest accuracy possible during high-speed machining. These guideways provide 30-percent stronger rigidity than regular linear-ball guideways. The machine is also equipped with 16-station live tooling, twin spindles, a Sauter turret and big-bar capacity that provides machining flexibility.

|

|

FCL-130RP High-speed, Linear Way CNC Lathe

The FCL-130RP, designed with a 30-degree slant bed, incorporates both a gantry-type parts loader and unloader and tailor-made feeding station for increased volume production. The compact, shorter machine design features a small footprint. Also included is a graphical user interface and built-in customized program that delivers shorten production and cycling times.

|

|

Chevalier is increasing the use of digital platforms to clearly demonstrate how our machines provide innovative solutions

The frequency of conducting business virtually has greatly accelerated since the onset of the COVID-19 global pandemic and experts believe this trend will continue. Here are three successful ways that Chevalier is virtually engaging customers and demonstrating the many benefits of partnering with us.

- Chevalier collaborated with the Taiwan External Trade Development Council to produce a 360-degree factory tour system, which conveniently allows overseas customers to virtually visit Chevalier’s production line and learn how Chevalier’s smart machinery and precision manufacturing can meet their evolving needs. Link: https://360.smartmachinery.com.tw/vr/standard/Chevalier/index.html

- We recently participated in the online presentation of "Taiwan Smart Manufacturing Seminar in Indonesia." Through the 360-degree factory tour, Chevalier discussed our exciting new initiatives and shared how we are providing innovative solutions for the electric vehicle industry. Link: https://www.youtube.com/watch?v=ALQFfXaRFRA

- Our company partnered with a well-known German industrial magazine, MM MaschinenMarkt, to prepare a special report, entitled, "Taiwan: Latest Solutions for Electric Vehicle Components Manufacturing." This report documents how Chevalier grinders successfully provide solutions for the EV industry and how we educate customers with a thorough explanation of EV parts manufacturing. Link: https://reurl.cc/em1X7L

|

|

|

|

Chevalier shared the information of electric vehicle applications at the conference in Indonesia.

|

|

|

TIMTOS X TMTS2022 Taipei International Machine Tool Show

|

| Show Dates |

February 21-26, 2022 |

| Show Hours |

10:00-18:00 daily |

| Venue |

TAIPEI NANGANG Exhibition Center, Hall 1 (TaiNEX 1) |

| Address |

No.1, Jingmao 2nd Rd., Nangang District, Taipei City 11568, Taiwan |

| Registered Name |

Falcon Machine Tools Co., Ltd.

Focus cnc Co., Ltd. |

| Booth No. |

J1218 |

| Online Exhibition |

February 21 – March 21, 2022 |

|

|

|

|

Chevalier Chevalier

FSG-2048/64 ADIV FVGC Series

|

|

|

Focus cnc Download Chevalier

FNL-220 Series APP for more info.

|

|

|

|