|

Upgrade to Smart Manufacturing With Chevalier

|

|

|

Our grinders help the screw manufacturing industry stay competitive

With traditional industries facing gaps in talents and technology, now more than ever is the best time to transition from outdated manufacturing processes to smart manufacturing.

One such sector that would greatly benefit from smart manufacturing is the screw manufacturing industry. With diverse products, complex shapes, high machining accuracy requirements and short product life cycles, this industry requires senior engineers to complete jobs if smart manufacturing is not utilized. Various challenges have been encountered during attempts to stay in step with technological advances.

Our grinding machines, which use a diamond roller to process wheel dressing, incorporate graphical conversational software for a variety of thread rolling die grinding. This software eliminates the need for senior engineers to program settings. Operators need only to perform simple graphical operations to quickly complete system settings, which simplifies complex manufacturing processes and improves product accuracy and grinding efficiency.

|

|

|

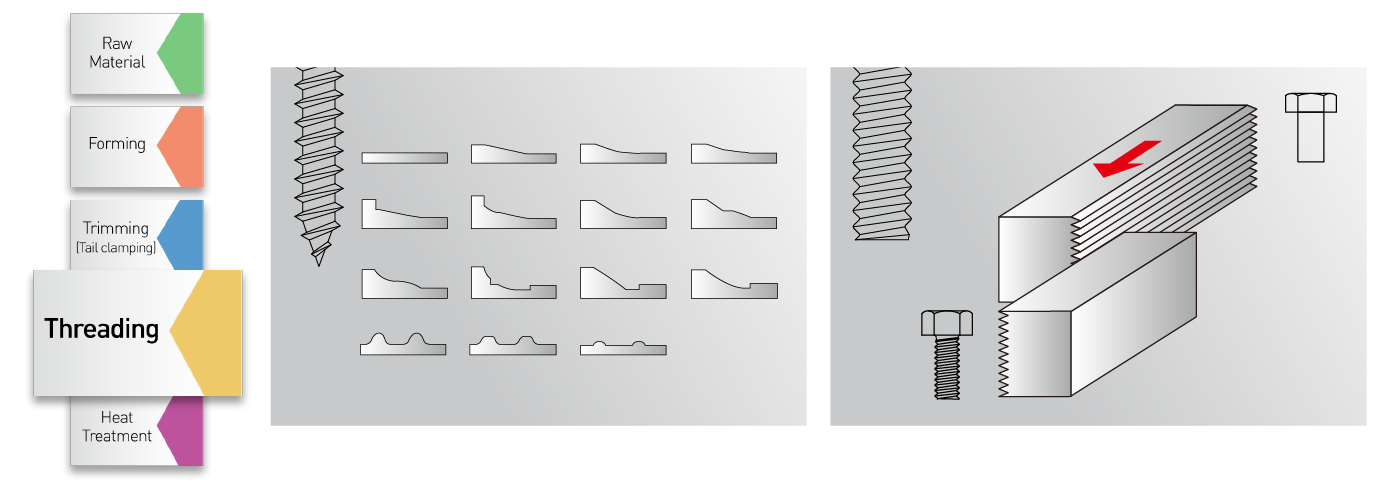

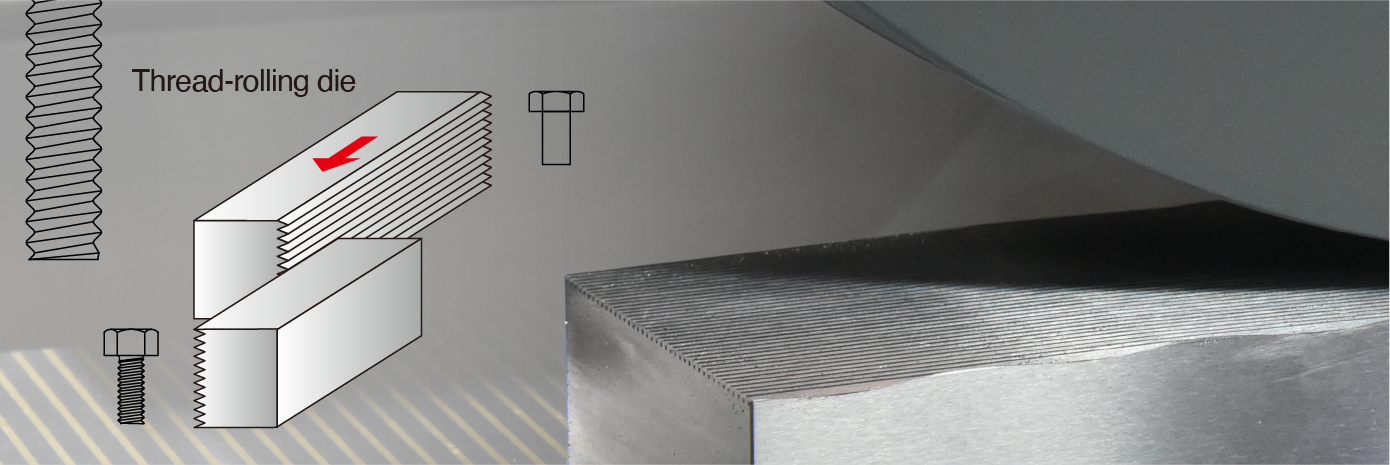

Screw Manufacturing Process

|

|

|

|

Thread-rolling die and threading, the key manufacturing processes for screws, are the major challenges for an industry heavily dependent on technology and talent.

|

|

|

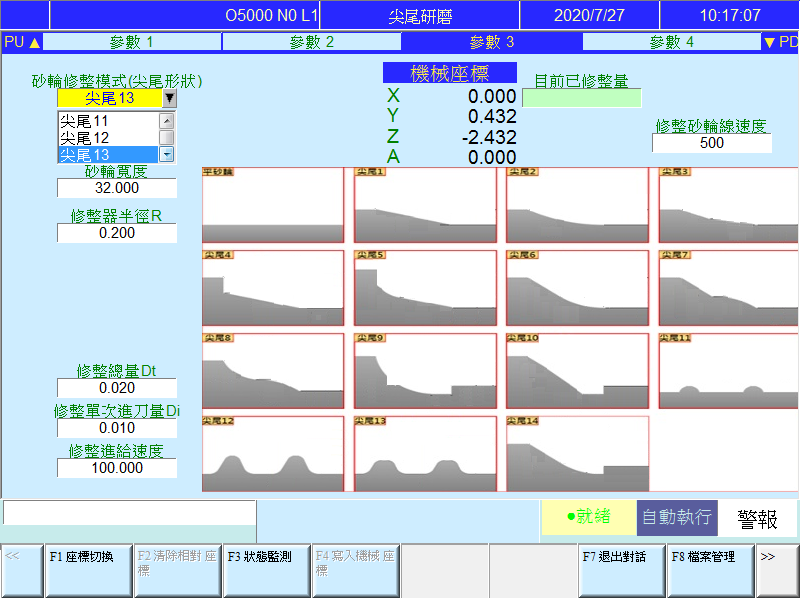

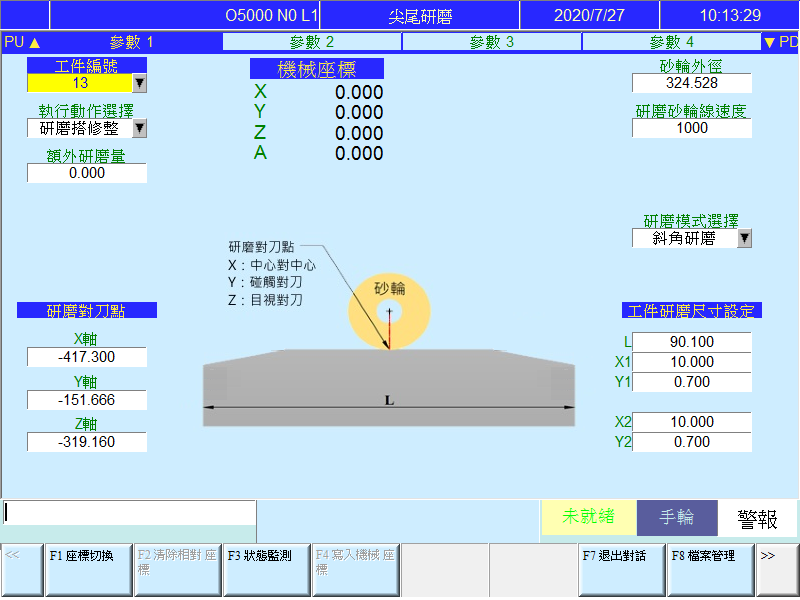

Chevalier’s SMART iControl simplifies grinding operations

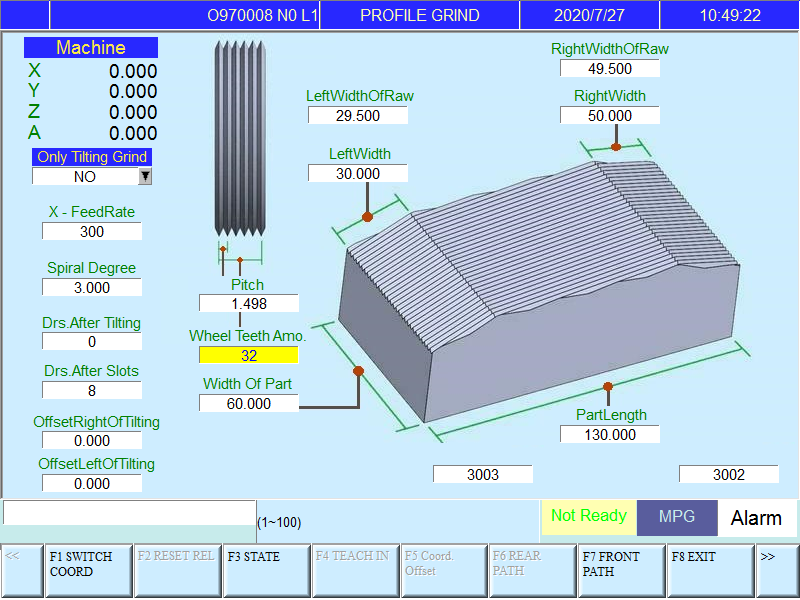

Use SMART iControl graphical conversational software to edit the path of shape and specification. The system automatically performs path calculation and completes the wheel dressing according to input parameters.

Use graphical conversational software to input machining conditions. The system can automatically plan the grinding path according to different specifications. Simultaneously, the grinding wheel can be dressed and compensated during grinding.

|

|

|

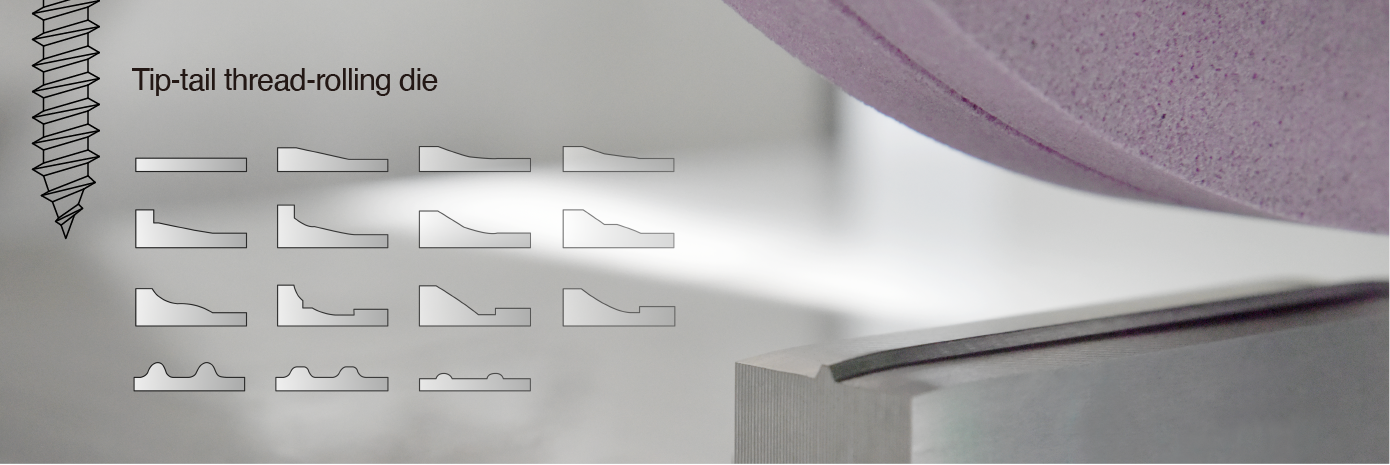

Tip-tail thread-rolling die solution

|

|

|

|

Screws for construction engineering, automotive, electronics and aerospace industries.

|

|

|

|

Graphic setting interface.

|

|

|

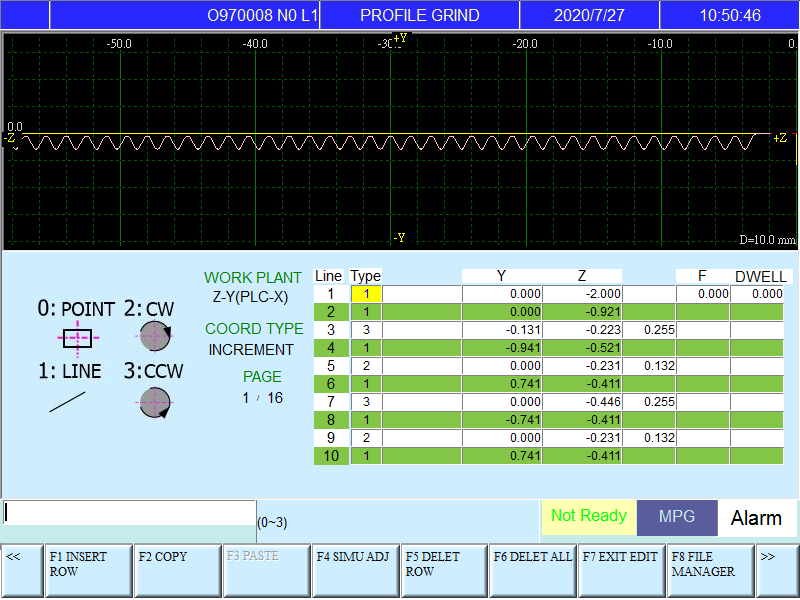

Graphic conversational operation interface for the thread-rolling die.

|

|

|

Thread-rolling die solution

|

|

|

|

Used in construction, engineering, automotive, machinery, electronics and aerospace industries.

|

|

|

|

Easy contour path editing.

|

|

|

Graphic conversational operation interface for the thread-rolling die.

|

|

|

The FMG-B1224’s traveling column allows operators to

easily grind complex workpieces

|

|

The FMG-B1224, a column-moving CNC-precision profile grinding machine, features the SMART iControl system, which meets the grinding application requirement of the above-mentioned thread-rolling die.

This machine’s benefits include: high precision, high efficiency and a small footprint. It features a large-diameter spindle and a low-center-of-gravity body structure with a moving column. It comes equipped with both a head-mounted dresser to enable continuous dressing during grinding and a high-pressure coolant system to greatly reduce machining time.

And, perhaps best of all, the SMART iControl graphical conversational software for thread- rolling die is easy to learn and operate, even for a novice.

|

|

|

New Video – FMG-B1224 thread-rolling die machining project.

|

|

|

|

For more information on industrial technical solutions, please contact your district office or email us at overseas@chevalier.com.tw

|

|

|

|

Falcon enthusiastically participates in a manufacturing training program by the TMBA.

|

|

|

Falcon plays key role in teaching the fundamentals of machine tools

The machine tool industry is faced with ever-increasing market requirements and tests. Many assembly procedures and techniques may seem simple, but mastering complex details are the key to achieving machine accuracy and stability. That said, establishing common assembly standards and techniques not only ensures machine accuracy, but is essential in order to compete with advanced machine tools manufactured in Europe, Japan and the United States.

With this in mind, Falcon enthusiastically participates in a manufacturing training program organized by the Taiwan Machine Tool and Accessory Builders’ Association and the government. During the COVID-19 pandemic, professional teachers provide on-the-job training to our employees with the goal of improving their technical capabilities of assembly, hand-scraping, measuring and quality verification, in order to upgrade product quality and competitiveness.

|

|

|

|

Product Literature for

FMG-B1224 and SMART-III Series

|

|

|

Product Literature for

UNi5X-400 and APP

|

|

|

|