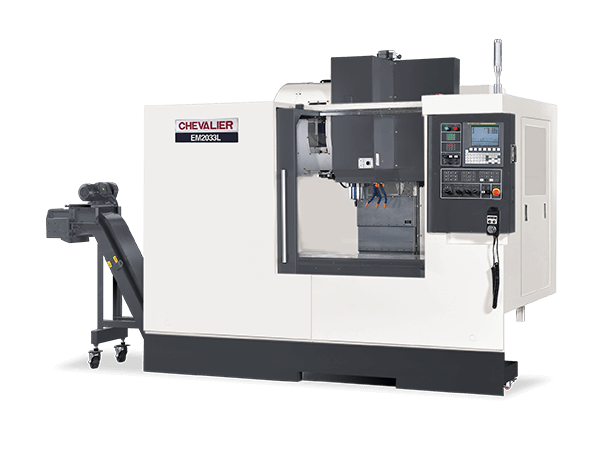

High-Speed Vertical Machining Center

The EM Series high-speed vertical machining center is a type of HSM machine that is designed to operate at higher spindle speeds and feed rates compared to a regular vertical machining center (VMC) for faster machining times. This makes them ideal for jobs that require quick turnaround times or high production rates that can satisfy the need for large-quantity machining.

This Series combination of high spindle speeds and advanced control systems enables them to achieve greater precision and accuracy in machining operations for tasks that demand tight tolerances and fine surface finishes.

EM Series major parts of the high-speed vertical machining center are constructed with high-density cast iron offers superior stability. The machine's base is supported by full travel, enabling it to be suitable for high-speed machining. All three axes are built in high-speed linear ways providing smooth quick movement without delay.

This series of high-speed vertical machining centers is the best value for the money and delivers more bang for your buck. Choose from three models: EM1620L, EM2033L and EM2040L, welcome to inquiry!

| Item | Description | EM2033L |

|---|---|---|

| Table | Table size | 1,000 x 510 mm (39.4" x 20.1") |

| Max. table load | 500 kg (1,100 lbs.) | |

| Travel | X-travel | 850 mm (33.5") |

| Y-travel | 530 mm (20.9") | |

| Z-travel | 510 mm (20.1") | |

| Spindle | Spindle nose to table surface | 150~660 mm (5.9"~26.0") |

| Spindle center to column | 585 mm (23.0") | |

| Spindle taper | #40 BIG PLUS | |

| Spindle speed | Belt drive: 10,000 rpm, optional 8,000/12,000 rpm Direct drive: 10,000 rpm, optional 12,000 rpm |

|

| Spindle diameter | Ø70 mm (Ø2.8") | |

| Feed rates | Rapid traverse (X/Y/Z) | 36/36/24 m/min (1,417/1,417/944 ipm) |

| Cutting feed (X/Y/Z) | 1~10 m/min (39.3~393 ipm) | |

| Automatic tool changer | Tool storage capacity | 24+1 arm type |

| Tool shank | BT40, optional CT40* or DIN40 | |

| Tool change time (T-T) | 3 sec. | |

| Pull stud | P40T-1 | |

| Max. tool diameter with adjacent tool | Ø80 mm (Ø3.1") | |

| Max. tool length | 300 mm (11.8") | |

| Max. tool weight | 7 kg (15.4 lbs.) | |

| Machine dimension | Floor space (W x D x H) | 2,360 x 3,020 x 2,600 mm (92.9" x 118.9" x 102.4") |

| Net weight | 5,800 kg (12,700 lbs.) |

| Item | Description | EM2040L |

|---|---|---|

| Table | Table size | 1,200 x 510 mm (47.2" x 20.1") |

| Max. table load | 600 kg (1,320 lbs.) | |

| Travel | X-travel | 1,020 mm (40.2") |

| Y-travel | 530 mm (20.9") | |

| Z-travel | 510 mm (20.1") | |

| Spindle | Spindle nose to table surface | 130~640 mm (5.1"~25.2") |

| Spindle center to column | 585 mm (23.0") | |

| Spindle taper | #40 BIG PLUS | |

| Spindle speed | Belt drive: 10,000 rpm, optional 8,000/12,000 rpm Direct drive: 10,000 rpm, optional 12,000 rpm |

|

| Spindle diameter | Ø70 mm (Ø2.8") | |

| Feed rates | Rapid traverse (X/Y/Z) | 36/36/24 m/min (1,417/1,417/944 ipm) |

| Cutting feed (X/Y/Z) | 1~10 m/min (39.3~393 ipm) | |

| Automatic tool changer | Tool storage capacity | 24+1 arm type |

| Tool shank | BT40, optional CT40* or DIN40 | |

| Tool change time (T-T) | 3 sec. | |

| Pull stud | P40T-1 | |

| Max. tool diameter with adjacent tool | Ø80 mm (Ø3.1") | |

| Max. tool length | 300 mm (11.8") | |

| Max. tool weight | 7 kg (15.4 lbs.) | |

| Machine dimension | Floor space (W x D x H) | 2,720 x 3,020 x 2,600 mm (107.0" x 118.5" x 102.4") |

| Net weight | 6,200 kg (13,600 lbs.) |